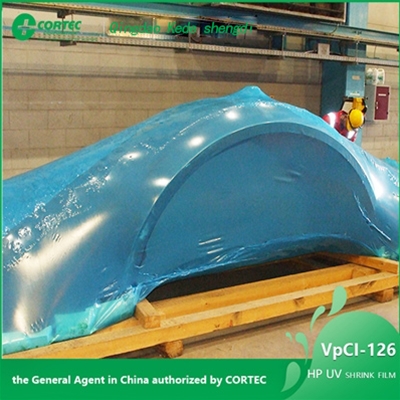

VpCI is a new type of RP material, it is necessary to understand the nature of it, only to master its characteristics, in order to make it play an excellent best effect in RP work. Its characteristics are introduced as follows:

Induction period:

Volatile diffusion of vapor phase corrosion inhibitors to the protection of the surface of the workpiece, when reach a certain concentration, the protection of metal formed resistance, corrosion inhibitor, this time is called the induction period, but when it does not protect the concentration may commonly, effect factors to cause rust and corrosion in the metal, the more serious corrosion has occurred, is a large amount of oxygen and moisture adsorption, So that it has the ability to continue the rust reaction, leading to the failure of vapor phase rust protection, therefore, how to prevent rust in the induction period is a very key technology. People have always wanted to induction period shorter as far as possible, in addition, the induction period also agents and the vapor pressure, rust distance and workpiece material all have relationship, if in practical use due to induction period longer rust, high vapor pressure can be used with relatively low vapor pressure, the drug combination to solve, also can pack in space with desiccant moisture absorption solution first.

Dosage:

RP dosage due to packaging sealing and RP period requirements are different; Also different from the characteristics of vapor phase RP agent itself, for example: a commonly used long induction period of vapor phase RP agent dosage is 35g/m, and another short induction period of the dosage is as long as 10g/m, but long due to low vapor pressure, volatilization is slow, RP period is very long; The agent with a short induction period has a much lower lifetime although its initial rust resistance is good. In addition, the amount of packaging sealing is 1-4 times more than normal, which is because of poor sealing and large consumption. At the same time, the rust prevention period is long, and the use of agents shall be more.

Packing tightness:

Because the vapor phase rust inhibitor depends on the surface of the workpiece gathered up nearly saturated rust inhibitor concentration, because there needs to be a small environment and the atmosphere does not flow, this requires that the packaging has good sealing, otherwise, the ceramic vapor in the small environment of rust vapor out of the saturated state, rust prevention failed. On the other hand, because the seal is not good, the vapor phase rust inhibitor can not reach saturation will continue to decompose, causing abnormal consumption will greatly shorten the protection period.

Temperature effect:

When the temperature reaches above 60℃, most of the VpCI will decompose rapidly. Therefore, the hot workpiece will excessive consumption of vapor phase RP agent, it is best to use vapor phase RP material packaging after the workpiece is fully cooled.

Humidity impact:

The influence of humidity on metal corrosion is always very large, and the influence of humidity shall be minimized in application. General induction period of longer vapor phase rust inhibitor is more suitable for the relative humidity is less than 45% less than the environment, and relative humidity is greater than 80% to use the induction period of short vapor phase rust inhibitor.

Qingdao Kede, expert of VpCI engineering! Welcome consult and guidance at any time!

Service Hotline

Service Hotline