Rust removal setups range from simple to complex depending on the size of the components and the length of the job. For example, a one-time job to clean up a handful of rusty parts around the facility may only mean that maintenance needs three dishpans and a mesh steamer basket to dip and remove very small items such as nuts and bolts. Another option for sporadic rust removal is to place the rust removal solutions in portable self-contained units that can be moved from one part of the plant to another without spilling concerns. If rust removal is a recurring activity, workers may want to install permanent tubs in a designated area. In some cases, tubs will need to be large enough to hold a giant gear or valve, and cranes may be needed to raise and lower the part. If desired, bubblers and heaters can be added to speed up the rust removal action of VpCI®-422.

How to Remove Rust

Once the stations are set up, rust removal proceeds as follows:

- Clean and degrease the part if needed.

- Immerse the part in VpCI®-422 for one hour to 0.5 hours depending on the severity of the rust. Workers may check the components periodically to see how rust removal is proceeding.

-

Dip the parts in plain water to rinse away any residual VpCI®-422 and corrosion products so as not to contaminate the final neutralizing bath. At this stage, the worker can proceed to the final rinse or perform another round of rust removal.

-

Dip satisfactory parts in an alkaline cleaner such as VpCI®-414, which neutralizes the acid and inhibits flash rust.

-

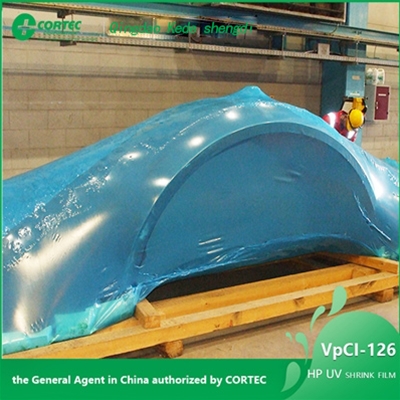

Dry the parts and preserve them against further rusting in storage or transit. This step can take a variety of forms, including dipping the part into a bath of VpCI®-377 or BioCorr® water-based rust preventatives or simply enclosing the dry part in VpCI® Film and Bags or other VpCI® packaging material.

Contact Qingdao Cortec to learn more about setting up a rust removal station at your facility!

2. Immerse the part in VpCI®-422 for one hour to 24 hours depending on the severity of the rust. Workers may check the components periodically to see how rust removal is proceeding.

Service Hotline

Service Hotline